The Difference Between Liquid Culture, and Liquid Inoculant.

The Memoirs of a Mushroom Genetic Hoarding Surfer. When it comes to inoculating grain spawn, the options are plentiful and Liquid Culture is a popular one. As a grower, I understand the importance of quickly colonizing grain spawn. This ensure its sterility and promote robust growth in later stages.

Personally, I prefer using a wedge of agar to transfer to grain, and then proceed to transfer to more bags. It’s a straightforward method that yields impressive results. The Grain-to-Grain (G2G) technique is truly remarkable and suitable for all levels of mycologists. This should always be considered when the clean room conditions are effectively maintained and the colonized grain is ready to go. Another approach I find effective is starting with liquid culture. By adding the agar to media bottles or mason jars, you can expand a single petri dish of colonized mycelium. This process will spread the mycelium to dozens of liquid culture jars.

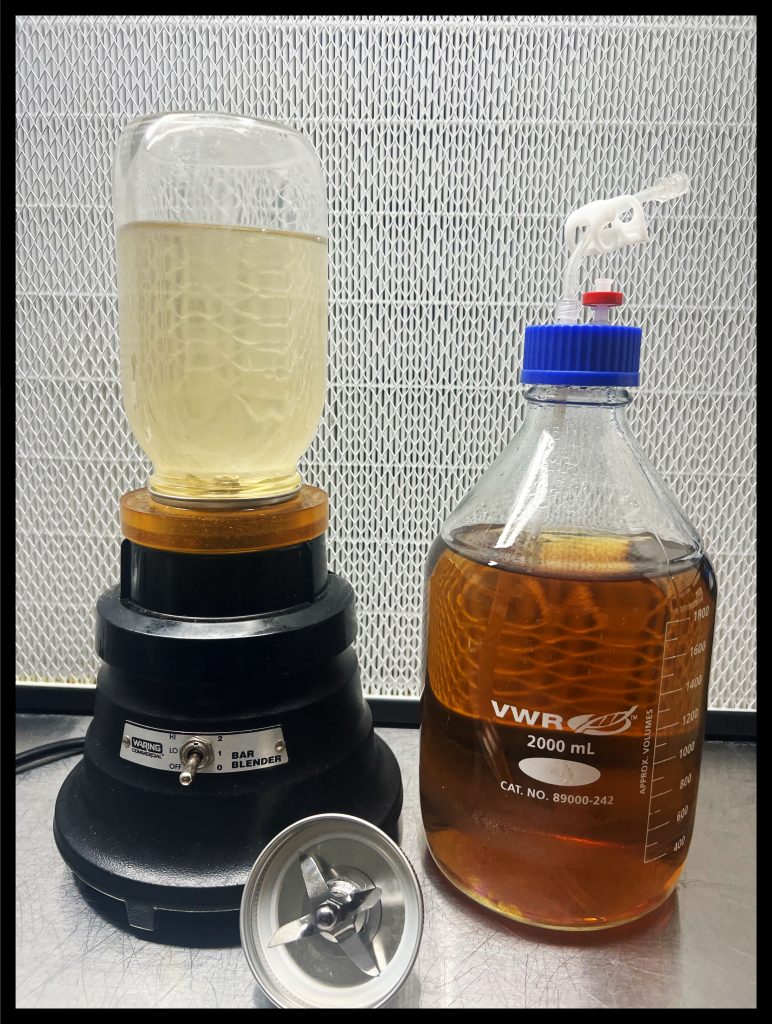

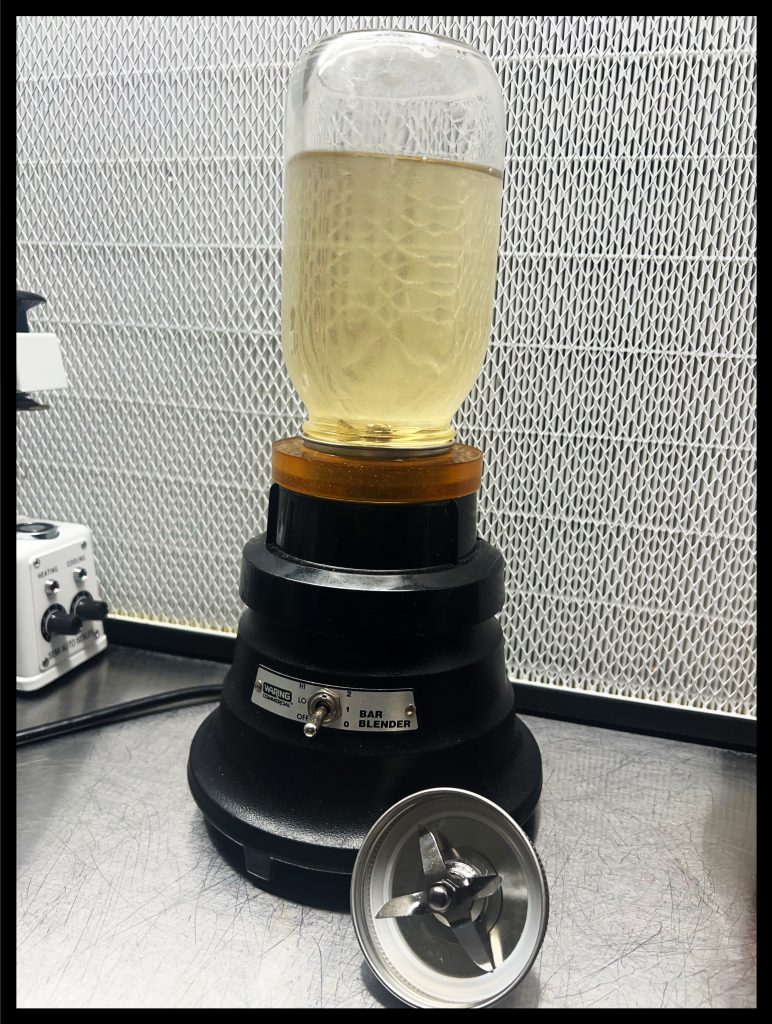

After incubating them for 14 days, you’ll have a substantial amount of inoculant ready for use. Lastly, there’s liquid inoculant, which offers instant liquid culture. This method involves using a blender head to pulverize your colonized agar in a nutrient-rich broth, accelerating the homogenizing process. Within moments, you can proceed to inoculation.

Liquid culture recipes and procedures can go in so many different directions and yield a variety of results. The most important thing to remember when using liquid culture is always add a magnetic stir pill first. This ensures you don’t forget to add the pill after filling with water and nutrients. Once the jar is sterilized you cannot add the pill after. Sterilize your liquid culture solutions for at least 40 minutes to ensure the material is properly cleaned. Many other recipes recommend 20-30 minutes and this is clearly not enough time for most pressure cookers All American , presto canner , even the 150 liter industrial autoclaves will not sterilize liquid culture in 20-30 minutes. Once your media has cooled down, you will add an agar wedge. Then turn on the magnetic stir plate to colonize for 2 weeks. After 2 weeks the quality control process begins by dropping liquid (2-3cc) onto an agar plate and waiting for clean white mycelium to form on the surface and not a grey/milky ooze. The QC (quality control plate) will show bad growth within 24-48 hours where mycelium will take about 3-5 days to appear depending on temperature. Around 75 F will be best for incubating a QC plate, please note even clean mycelium will appear to look like bacteria first 2-3 days then it will turn white on day 4-5.

Until this point grain transfers and liquid culture were the standard for expanding grain spawn. Liquid Inoculant is arguably the most accelerated technique in the world for growing mushrooms in high volumes. The difference between liquid culture and liquid inoculant is the latter does not need any time to incubate and technically can be used instantly. The same process for sterilizing is key, 40 minutes at 15 PSI sterilization cycle. The blender head of a commercial waring blender can be fixed onto a stainless steel mason jar lid with a 3/4 inch hole cut in the center of your lid(regular mouth works best) When you add an entire agar plate (or two) into the liquid inoculant jar and blend the entire jar

becomes homogenized with culture and your ready to go. The benefit on blending agar into liquid inoculant is this creates an instant culture ready to be used on the fly. When you work on a farm the time line to get anything ready for production is stressful enough, trimming off weeks this is by far the biggest bottle neck growers face. Mushrooms grow so fast yet commercial farmers are always chasing they’re tails to stay ahead. Liquid inoculant can alleviate all the most common pitfalls endured when mushroom growers scale their business. As the industry becomes more competitive and supply exceeds demand efficiency will be apparent to survival in both the culinary and holistic market.